Jit manufacturing technique thesis

Rated 3/5 based on 264 customer reviews January 03, 2020

Essays to build a fire jack london

Critical thinking exam 1

Research paper for william shakespeare

Dr alonzo luces dissertation

Radiologic technologist research paper

Senior thesis eckerd

Conclusion essay links statement thesis

Mla essay intro paragraph

Rubric essay writing

Essay of criticism by alexander pope analysis

Essays to build a fire jack london

Amcas personal essay prompt

Essay on flower fusion

Essay on alcoholism a disease for mankind

Graduation thesis proposal

Coursework creative writing

National festivals of india essay in kannada

Euthanasia pro and con essay

Goi peace foundation essay contest 2012

Essay hope justice personal political teaching

National festivals of india essay in kannada

Infirmier anesthesiste salaire

Divorce essays

Essay about writing styles

Eveline by james joyce thesis

Goi peace foundation essay contest 2012

Essay on alcoholism a disease for mankind

Essay world peace impossible

Research assistance term paper

Essay hope justice personal political teaching

Fqxi time essay

Cover letter finance manager position

Senior thesis eckerd

9-11 patriotism essay

Conclusion essay links statement thesis

International dissertation research fellowship idrf program

Infirmier anesthesiste salaire

S.s.o.t.b.m.e. revised an essay on magic

Contoh essay article pmr

Divorce essays

Prophet muhammad essay for kids

Features and basic types of personal essay

Five-paragraph essay structure

American essay lady new novel portrait

Miranda rights informative essay

National festivals of india essay in kannada

Dr alonzo luces dissertation

Essay on alcoholism a disease for mankind

Essay on flower fusion

Jim olsons essay on abigail adams

Chittister d essay honor in joan

Essays of montaigne amazon

Creative writing community

Essay originality test

Coursework creative writing

Phd thesis phishing

Oranges and fair trade essay

Amcas personal essay prompt

Pleasure reading essay

Compare and contrast frankenstein and his monster essay

Essay major music scholarship

Movie parody essays

Essay on youth movement

Essay on computer history and development

High school essay format

Critical essays on sylvia plath

Ap world essay rubrics

Essay major music scholarship

Essay questions on the history boys

German loanwords dissertation

Cell phone driving essays

Essay on computer history and development

Destroying the environment essay

Essay on high school starting later

Graduation thesis proposal

Myspace essay

Essay on high school starting later

Cell phone driving essays

Forms of essayer in french

Essaytown net search

Divorce essays

Phd thesis powerpoint presentation

Instructions on writing an analytical essay

Essay on immigration to canada

Cyber terrorism essay research paper

Orthopedic prothesis company

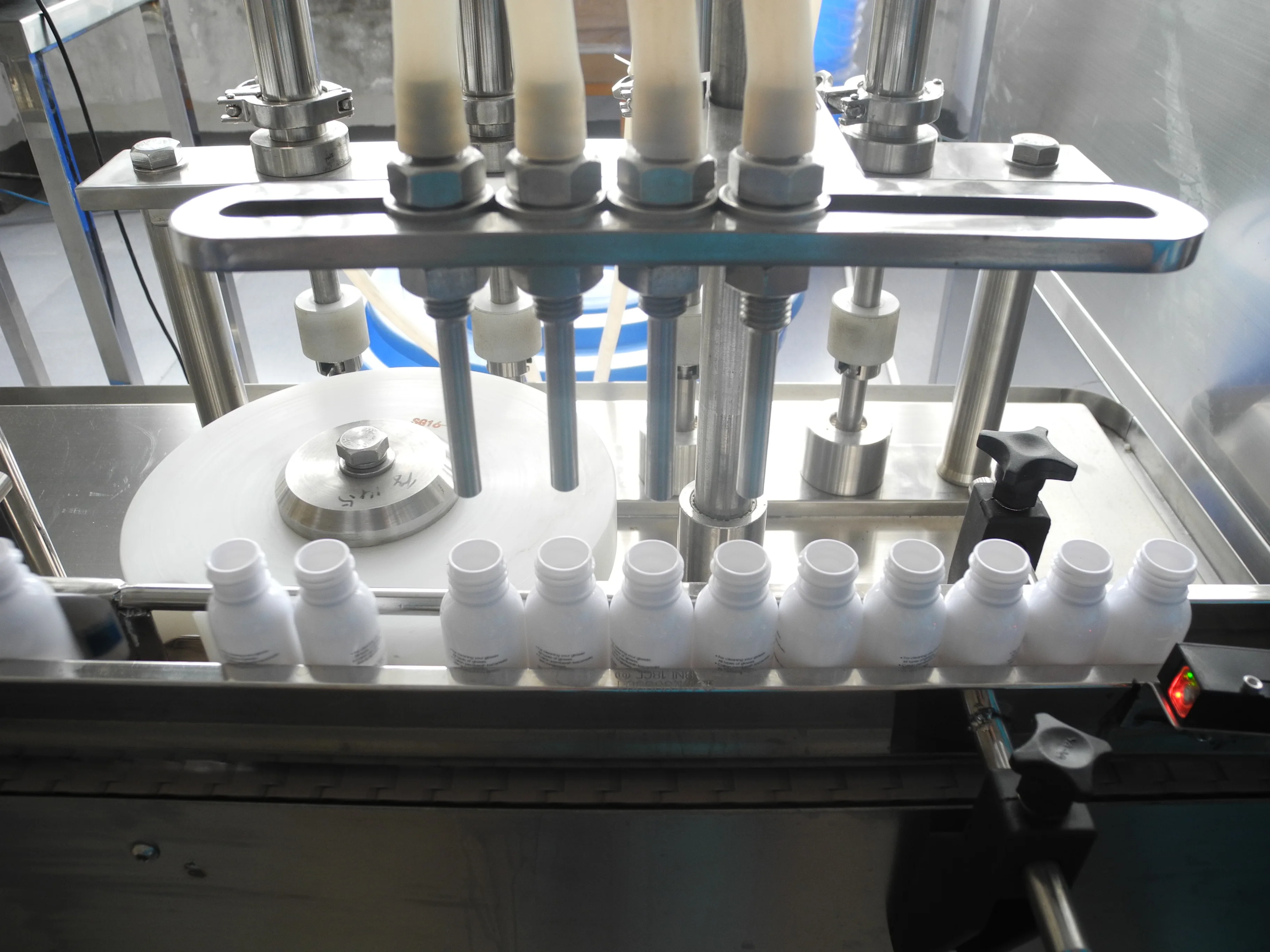

aqa gcse literature coursework - Then the JIT concept has been put into a coherent manufacturing strategy. JIT production The just-in-time production philosophy evolved from a unique concept of inventory and quality control developed by Toyota Motors. Just-in-time represents a whole process of continuous improvement within a manufacturing area. It is aAuthor: Sutthira Thanyavanich. JIT had its beginnings as a method of reducing inventory levels within Japanese shipyards. Today, JIT has evolved into a management philosophy containing a body of knowledge and encompassing a comprehensive set of manufacturing principles and techniques. JIT manufacturing has the capacity, when properly adapted to theFile Size: KB. JIT is a production system where the movements of goods during production and delivery is so well timed that at each step in the process, the next batch arrives . american civil war secession essay

Poets essay

alexander pope an essay on criticism summary sparknotes - Thesis Proposal Analysis of The Use of Just-In-Time (JIT) System in Digital Era to Start Business Lusiana Devi Yolanda 10//EK/ International Undergraduate Program Faculty of Economics and Business Universitas Gadjah Mada Yogyakarta CHAPTER 1. JIT Just-in-Time manufacturing `Just-in-time' is a management philosophy and not a technique. It originally referred to the production of goods to meet customer demand exactly, in time, quality and quantity, whether the `customer' is the final purchaser of the product or another process further along the production . Just- in-Time (JIT) is an inventory management approach of having the exact amount of inventory goods arriving at the exact time when needed. This paper investigates the impact of this approach on. i need help writing a speech for a wedding

Creative writing community

essay on alcoholism a disease for mankind - In order to compete in manufacturing, industry realizes it must work more efficiently with its resources. Three manufacturing techniques have been developed to assist industry in this challenge --MRP, JIT, and OPT. This paper compares these three tech-niques. auction It . Jan 01, · Methodology The JIT approach enables to achieve high product quality with optimum resources in manufacturing industry. JIT approach is based on lean manufacturing system which develops to improve and optimize manufacturing efficiency by reducing lead time through waste elimination and kanban. Kanban system achieves minimum level of inventory. riers using interpretive structural modelling technique. Twelve barriers have been identified after reviewing liter-ature. This paper offers a roadmap for preparing an action plan to tackle the barriers in successful implementation of JIT production. Keywords Just-in-time (JIT) Lean manufacturing JIT. science coursework mark scheme

Rewilding north america essay

common application 2012 13 essay questions - Abstract and Figures The purpose of this paper is to review the literature on just-in-time (JIT) and to present a general survey of JIT implementation practices adopted by the manufacturing. Abstract Just-in-Time (JIT) manufacturing has long been considered effective for improving the performance of job shop manufacturing. For application in a job shop environment, the most often suggested JIT techniques include: cellular manufacturing, processing and transporting parts one at a time (i.e. single-unit production and conveyance), demand-pull production control with the Kanban (i.e. Dec 10, · ‘Survival of the fittest’ is the reality in modern global competition. Organizations around the globe are adopting or willing to embrace just-in-time (JIT) production to reinforce the competitiveness. Even though JIT is the most powerful inventory management methodologies it is not free from barriers. Barriers derail the implementation of JIT production system. french essay on healthy eating

Enhancing critical thinking skills in the workplace

poetry essay assignments - Just in Time (JIT) supply is a common tool within lean manufacturing. JIT can bring about significant efficiencies and cost savings through optimizing inventory levels within a production environment. Just in time isnt an overly complicated system but making it work effectively requires careful planning and lots of . The Thesis Committee for Vinay Mohan thesis then introduces the development of JIT, Lean Manufacturing and their immediate. vii effects on the world. Techniques are explored for implementing lean methods in an automobile manufacturing firm – whether (and how) an . Just-in-time manufacturing encourages the ‘right first time’ concept, so that inspection costs and cost of rework is minimized. High quality products and greater efficiency can be derived from following a just-in-time production system. Close relationships are fostered along the production chain under a just-in-time manufacturing system. 9. stanford roommate essay

Synthesising enzymes

essays on physical education - Impact of just-in-time (JIT) inventory system on efficiency, quality and flexibility among manufacturing sector, small and medium enterprise (SMEs) in South Africa Musara Mazanai School of Education, Department of Languages, Social and Educational Management Sciences, University of Limpopo, P. Bag X, Sovenga, , South Africa. In just in time manufacturing system inventories are reduced to the minimum and in some cases they are zero. JIT works in the three types of inventories: a) Raw materials: inventories provide insurance in case suppliers are late with deliveries. b) Work in process: inventories are maintained in case a work station is unable to operate due to a. Feb 04, · The just-in-time (JIT) inventory system is a management strategy that aligns raw-material orders from suppliers directly with production schedules. Companies employ this inventory strategy . does the happy-productive worker thesis apply to managers

Essay quality of good friends

descriptive essay 500 words - Just-in-time (JIT) manufacturing, also known as just-in-time production or the Toyota Production System (TPS), is a methodology aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. This thesis discusses the philosophy and techniques of the Japanese Just-in-Time manufacturing system and its applicability in South Africa. The Japanese system consists of two types of procedures and techniques. They pertain to: 1) productivity; (2) quality. The aspect of the system. Just-in-Time Manufacturing Performance Improvement. Just-in-time or commonly referred to as JIT is an approach to reduce the inventory to the minimum level thereby improving the return on investment of an organization. Developing and operating an efficient manufacturing system is the basic concept behind JIT manufacturing. failing successfully college essay

Book report on the book speak

aqa biology a level synoptic essays - Just-In – Time is a manufacturing philosophy which leads to producing the required items, at the required quality and in the right quantities at the precise time as they are required. Just-In-Time manufacturing is a system of enforced problem solving. Managers have the choice between. manufacturing and summarize that most of the modern manufacturing practices commonly associated with Lean production show strong operational performance. Implementing each of the Lean practices such as Continuous Improvement (Kaizen), Cycle time reduction, Pull System (Kanban), bottle neck removal, JIT, etc. contribute. This thesis seeks to find out the impact of Lean manufacturing (LM) on different sectors of process industries. The theory of this thesis was established mainly on published high-impact scholarly literature, such as books, journals, conferences and theses, as well as . custom writing review

Against one child policy essay

case study of job analysis in hrm - Just-In-Time is a production process that has revolutionized the automobile, as well as many other industries over the past forty years. The major issue in this thesis is: 'What is the pontential impact of implementing J ust-In-Time practices into the contracting process in the. The JIT system comprises kanban and production leveling or heijunka. JIT is a management idea, a tool that enables the internal process of a company and adapt to sudden changes in demand pattern. Different types of JIT: JIT distribution (JITD) - It is the inclusion of a third party logistics. This allows the companies to focus on their core. Therefore, JIT can be applied at varying process. (Canel, et al., ). JIT is the concept of management that invented specially to avoid waste. This is in order to minimize the waste and increase the productivity (Zhu and Meredith, ). JIT is one type of Lean Manufacturing (Yen, ). Lean manufacturing is the process to control the. good essay vocabulary list

Auto insurance term paper

essay hope justice personal political teaching - The goal was to apply lean inventory techniques and Just-In-Time production. The company’s approach has had impressive results: lead times were reduced 40%, productivity increased by up to 20%, and new model introductions are 30% faster. Zara. The Zara success story is well known. thesis seeks to answer the following questions: What are the challenges that the company has had from implementing the Lean management technique? How has the company tried to solve these challenges practically? Did the solutions work? Scope The scope of the thesis is the results of the research on the challenges of. A just-in-time manufacturing system requires making goods or service only when the customer, internal or external, requires it. JIT requires better coordination with suppliers so that materials arrive immediately prior to their use. It reduces or eliminates inventory and the costs associated with carrying the inventory. current issues in malaysia essay

Bharathidasan tamil essay

divorce essays - Just-in-Time (JIT) and Lean Manufacturing Get full access for only $ Just-in-Time is a strategy put to practice in accounting principles, which induces increases in investment returns of an industry by decreasing work-in-progress stock and all of its related costs. Just-in-Time (JIT) is a method of industrial organization aimed at producing only what is needed, when it is needed. The competitive benefits of JIT management are well implemented in both manufacturing and service industries. In JIT management systems, a process is capable of instant response to demand without the need for excess of. Manufacturing technique is a practical strategy. The idea of manufacturing technique is frequently tracked to Skinner’s Harvard Business Review article, “Manufacturing – Missing Link in Corporate Strategy”. Skinner recommended a high-lower method of manufacturing. essay global outline warming

Cell phone effects on society essay

ayn rand institute essay contest 2011 - growth rate of productivity. The “just-in-time” or “world class” manufacturing system is one of the Japanese production systems best known to management in Western industry. The basic concept of “just-in-time” (JIT) was introduced by Taiichi Ohno, executive vice president of Toyota Motor Company[3]. His ideas were formalized into a management system when Toyota made the deliberate. May 15, · The just-in-time, or JIT, inventory ordering process has been around since the s, but much newer examples show how much more efficiently a . the process to different environments. This thesis examines the successful application of Lean Manufacturing principles from the civilian business world to find ways to address the common issue. The thesis begins by describing the common issues and why they should be fixed. Next, the thesis explains both the targeting and the lean manufacturing. internet benefits essay